In the world of procurement, every decision counts. Costs, quality, and supplier relationships all play a crucial role in business success. But how do you ensure you’re paying the right price for the products and services your company needs? Enter “should cost” modeling—a strategic approach that empowers procurement professionals to make smarter decisions and negotiate better deals. Mattias Knutsson, a highly experienced professional in global procurement, commodity management, and strategic business development, is a firm advocate of should cost modeling. With years of expertise in optimizing costs while maintaining quality, he emphasizes how this methodology can transform the way businesses approach supplier negotiations.

What Is Should Cost Modeling?

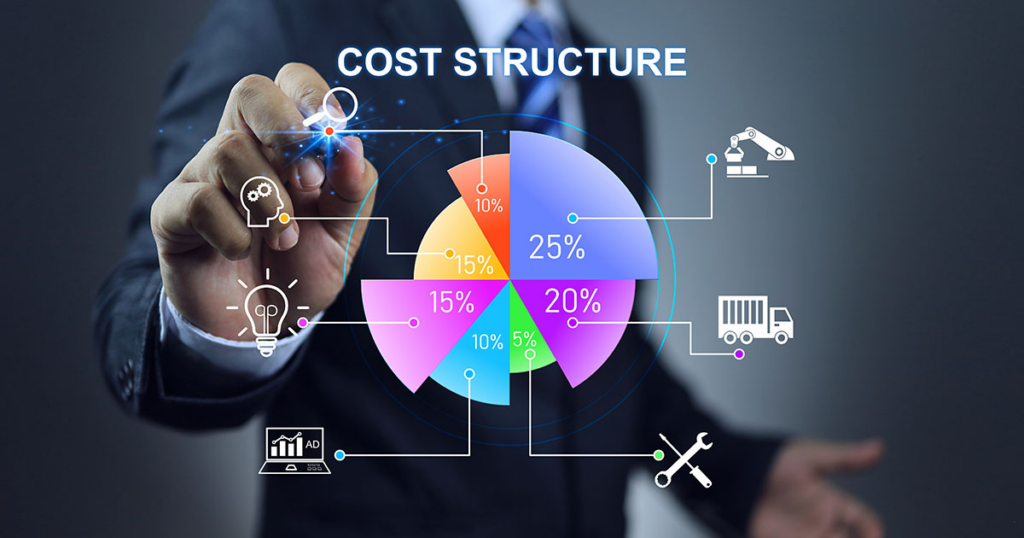

Should cost modeling is the process of estimating the cost of a product or service based on its underlying components, materials, labor, overhead, and profit margin. Rather than accepting supplier pricing at face value, it provides a transparent understanding of what a product or service should cost.

This approach enables procurement teams to identify cost drivers, benchmark prices, and engage in data-driven negotiations. It’s not about undercutting suppliers but ensuring fairness and fostering mutual value.

Why Should Cost Modeling Matters

It delivers several key benefits:

- Improved Negotiations: By knowing the cost structure, you can negotiate more effectively and secure better deals.

- Cost Transparency: It identifies areas where costs might be inflated or unreasonable.

- Enhanced Supplier Relationships: A collaborative approach to cost modeling builds trust and encourages open communication.

- Strategic Procurement Decisions: It highlights cost-saving opportunities, driving overall efficiency.

A recent Deloitte study revealed that companies using cost modeling saw a 15-20% reduction in procurement costs. This demonstrates the significant impact it can have on profitability and competitiveness.

Principles of Should Cost Modeling

1. Understand the Product Breakdown

Start by deconstructing the product or service into its core components. For example, in manufacturing, this could include raw materials, labor, packaging, and logistics. Each element contributes to the final cost and should be analyzed individually.

2. Research Market Benchmarks

Gather data on industry standards, material costs, and labor rates. Market research tools like IBISWorld and Statista can provide valuable insights to ensure your estimates are realistic.

3. Factor in Overheads and Margins

Suppliers have their own operating costs and profit margins, which are important to consider. A fair assessment of these elements fosters balanced negotiations.

4. Leverage Technology and Tools

Advanced tools like cost estimation software and AI-driven analytics simplify the modeling process. These tools can process vast amounts of data to deliver accurate cost predictions.

5. Engage Cross-Functional Teams

This modeling isn’t just for procurement teams. Involve engineering, finance, and operations to ensure a holistic approach. Their expertise can help refine estimates and identify additional cost-saving opportunities.

How Should Cost Modeling Enhances Negotiations

1. Builds Confidence and Credibility

When you approach a supplier with a well-researched cost model, it demonstrates your understanding of the market and production processes. This not only strengthens your position but also establishes credibility.

2. Encourages Collaboration

Rather than a confrontational negotiation, should cost modeling fosters a collaborative approach. Suppliers appreciate transparency and are more likely to engage in meaningful discussions.

3. Identifies Value-Added Opportunities

Through cost modeling, you can identify areas where costs can be optimized without affecting quality. For instance, suggesting alternative materials or streamlined processes can benefit both parties.

4. Supports Long-Term Partnerships

Negotiations based on data and fairness lead to stronger, long-lasting supplier relationships. Suppliers are more likely to prioritize clients who approach pricing discussions constructively.

Real-World Application

In industries like wood materials, where Mattias Knutsson has extensive experience, should cost modeling plays a critical role. For example, analyzing the cost structure of glued wood components can reveal opportunities to source materials more sustainably or improve production efficiency, leading to significant savings without sacrificing quality.

Challenges in Should Cost Modeling

While highly effective, cost modeling comes with challenges:

- Data Availability: Accessing accurate cost data can be difficult. Partnering with reliable market research firms can help bridge this gap.

- Supplier Resistance: Some suppliers may be hesitant to share cost details. Building trust and fostering transparency is key to overcoming this hurdle.

- Complexity in Estimation: Products with intricate designs or diverse components require detailed analysis. Cross-functional collaboration can address this complexity.

Conclusion

Should cost modeling is a game-changer in procurement, offering businesses the tools to make informed decisions and negotiate with confidence. By understanding the cost structure of products and services, companies can reduce expenses, improve supplier relationships, and maintain high standards of quality.

Professionals like Mattias Knutsson, with his deep expertise in global procurement and strategic business development, embody the transformative power of this approach. His success in identifying cost drivers and fostering collaborative supplier negotiations highlights the strategic value of cost modeling.

In an increasingly competitive market, adopting should cost modeling isn’t just an option—it’s a necessity for businesses striving for efficiency and sustainability. It’s time to move beyond guesswork and embrace a smarter, data-driven approach to procurement.