The manufacturing sector is no stranger to change. In 2024, businesses are navigating a rapidly shifting landscape shaped by macroeconomic trends. From evolving consumer demands to technological advancements, manufacturers must stay ahead to remain competitive. Understanding these trends and their implications is key to making informed decisions and positioning for success. Mattias Knutsson, an expert in global procurement and strategic business development, has a wealth of experience in navigating macroeconomic challenges. His insights emphasize the importance of understanding these macro trends and translating them into actionable strategies for the manufacturing industry.

Key Macro Trends Shaping Manufacturing in 2024

1. Economic Uncertainty and Inflationary Pressures

Economic volatility continues to impact the manufacturing sector in 2024. Persistent inflation is driving up raw material and energy costs, challenging manufacturers to manage expenses without compromising product quality. According to a report by PwC, 74% of manufacturing leaders cite cost management as their top priority this year.

Actionable Insight: Businesses can mitigate these pressures through value engineering and cost optimization strategies. By analyzing product designs and sourcing materials more efficiently, manufacturers can maintain profitability despite rising costs.

2. Focus on Sustainability and ESG Compliance

Environmental, social, and governance (ESG) considerations have moved from being optional to essential. Consumers and investors are demanding greater transparency and sustainable practices. The global market for green manufacturing is projected to grow by 15% annually, reflecting a clear shift toward sustainability.

Actionable Insight: Embrace sustainable practices by integrating renewable energy sources, reducing waste, and optimizing supply chains. Leveraging certifications and communicating your ESG efforts can also enhance brand reputation and attract eco-conscious customers.

3. Technological Advancements and Industry 4.0

The adoption of Industry 4.0 technologies—such as IoT, AI, and robotics—is accelerating. These advancements are transforming manufacturing processes, improving efficiency, and enabling predictive maintenance. According to McKinsey, companies that embrace digital transformation see a 25% increase in operational efficiency.

Actionable Insight: Invest in smart technologies that align with your production goals. Focus on data-driven decision-making by implementing IoT sensors and AI-powered analytics to optimize operations and reduce downtime.

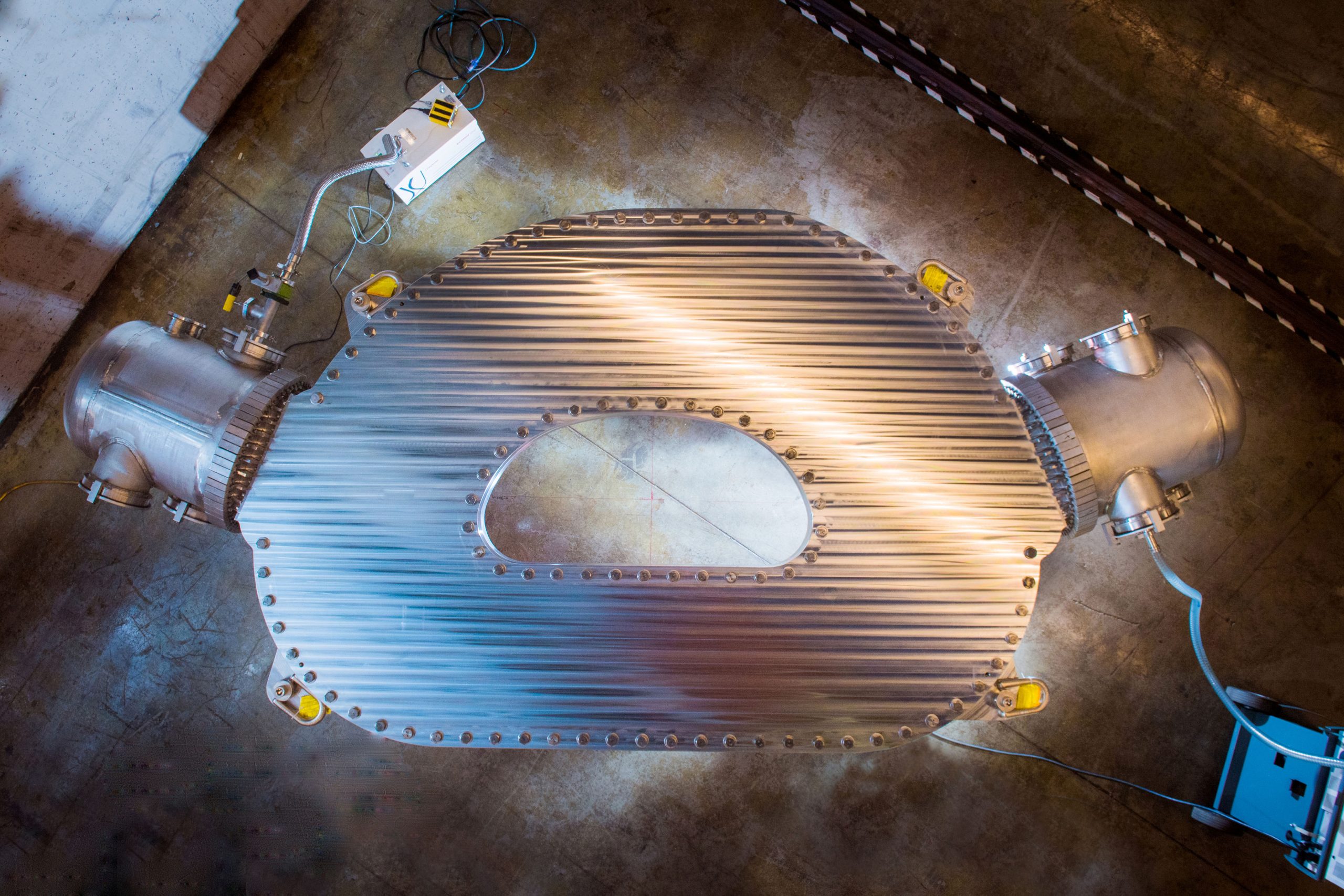

4. Global Supply Chain Reconfigurations

Geopolitical tensions and the aftermath of the pandemic continue to disrupt global supply chains. Manufacturers are rethinking their sourcing strategies, with many adopting nearshoring or reshoring to reduce dependency on distant suppliers.

Actionable Insight: Build resilient supply chains by diversifying suppliers and adopting local sourcing strategies. Collaborative relationships with suppliers and real-time tracking tools can enhance transparency and minimize disruptions.

5. Labor Market Challenges and Workforce Transformation

The manufacturing industry is facing a skilled labor shortage, with 77% of manufacturers struggling to fill critical roles. At the same time, automation is transforming the workforce, requiring employees to upskill and adapt to new technologies.

Actionable Insight: Invest in employee training and development programs to build a future-ready workforce. Partnerships with educational institutions and apprenticeships can help bridge the skills gap. Additionally, fostering a culture of innovation and inclusivity can improve employee retention.

6. Shifting Consumer Preferences

Consumer expectations are evolving rapidly, with increased demand for customization, fast delivery, and sustainable products. E-commerce continues to grow, challenging manufacturers to adapt to omnichannel supply chains.

Actionable Insight: Prioritize flexibility in production to accommodate customization. Adopt agile manufacturing practices and enhance your digital presence to cater to tech-savvy consumers.

Preparing for Macro Trends Success in 2024

Understanding and responding to macro trends is critical for manufacturers aiming to thrive in 2024. Business leaders must adopt a proactive mindset, leveraging these manufacturing industry macro trends as opportunities to drive innovation and growth.

Key Strategies to Consider:

- Embrace sustainability as a core business value.

- Invest in digital transformation to boost efficiency.

- Build resilient and flexible supply chains.

- Focus on workforce development to address labor challenges.

- Align products and services with evolving consumer demands.

Conclusion

The manufacturing industry in 2024 is navigating a complex landscape of economic challenges, technological advancements, and shifting consumer behaviors. By understanding these macro trends and adopting actionable strategies, manufacturers can turn challenges into opportunities and position themselves for long-term success.

Mattias Knutsson, a seasoned expert in global procurement and strategic business development, exemplifies how businesses can thrive amid these changes. His ability to align business strategies with macroeconomic realities ensures that companies not only adapt but lead in an ever-evolving industry.

The key to success lies in preparation, innovation, and a commitment to excellence. By staying ahead of these trends, manufacturers can create a stronger, more resilient future.